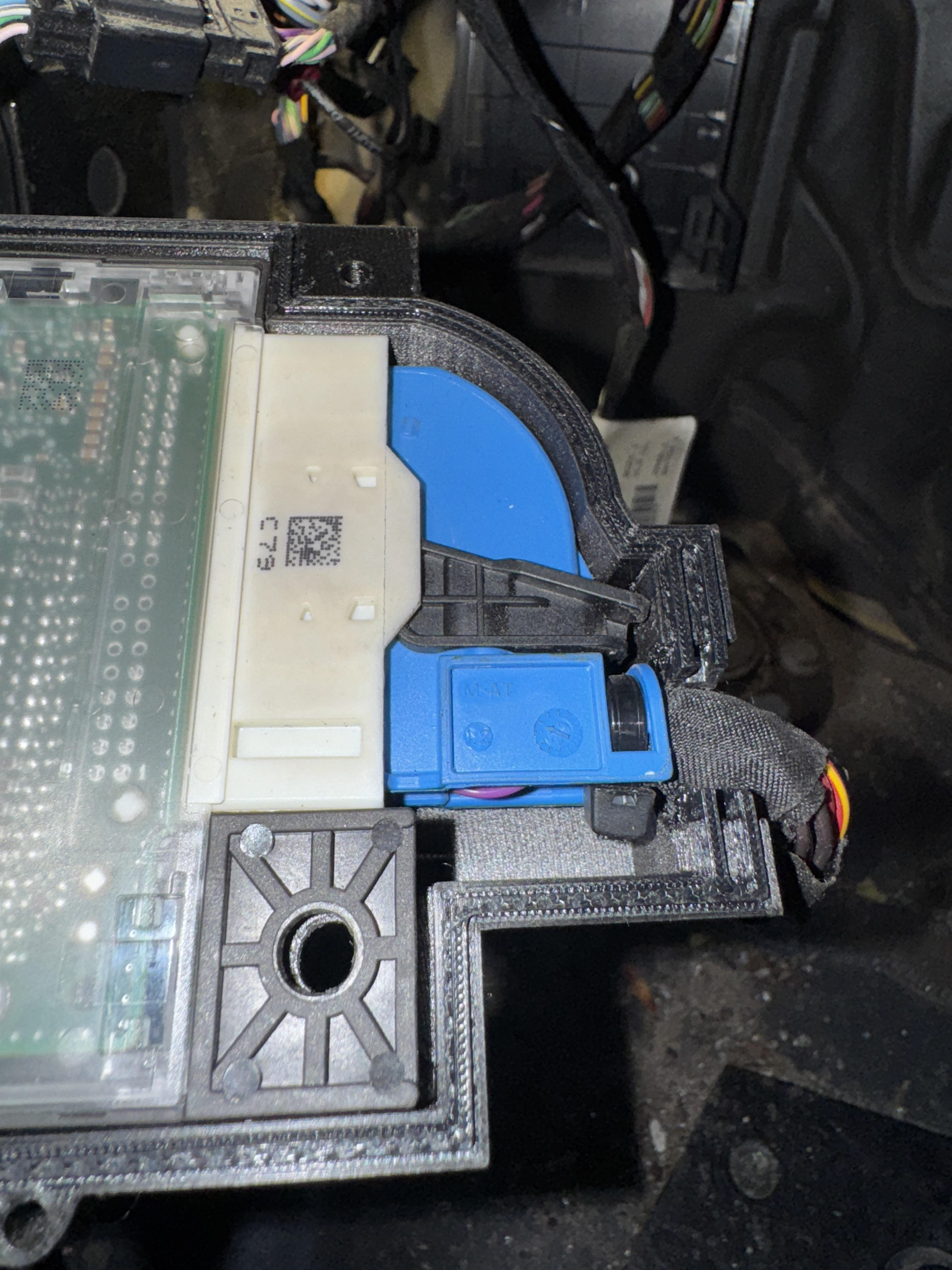

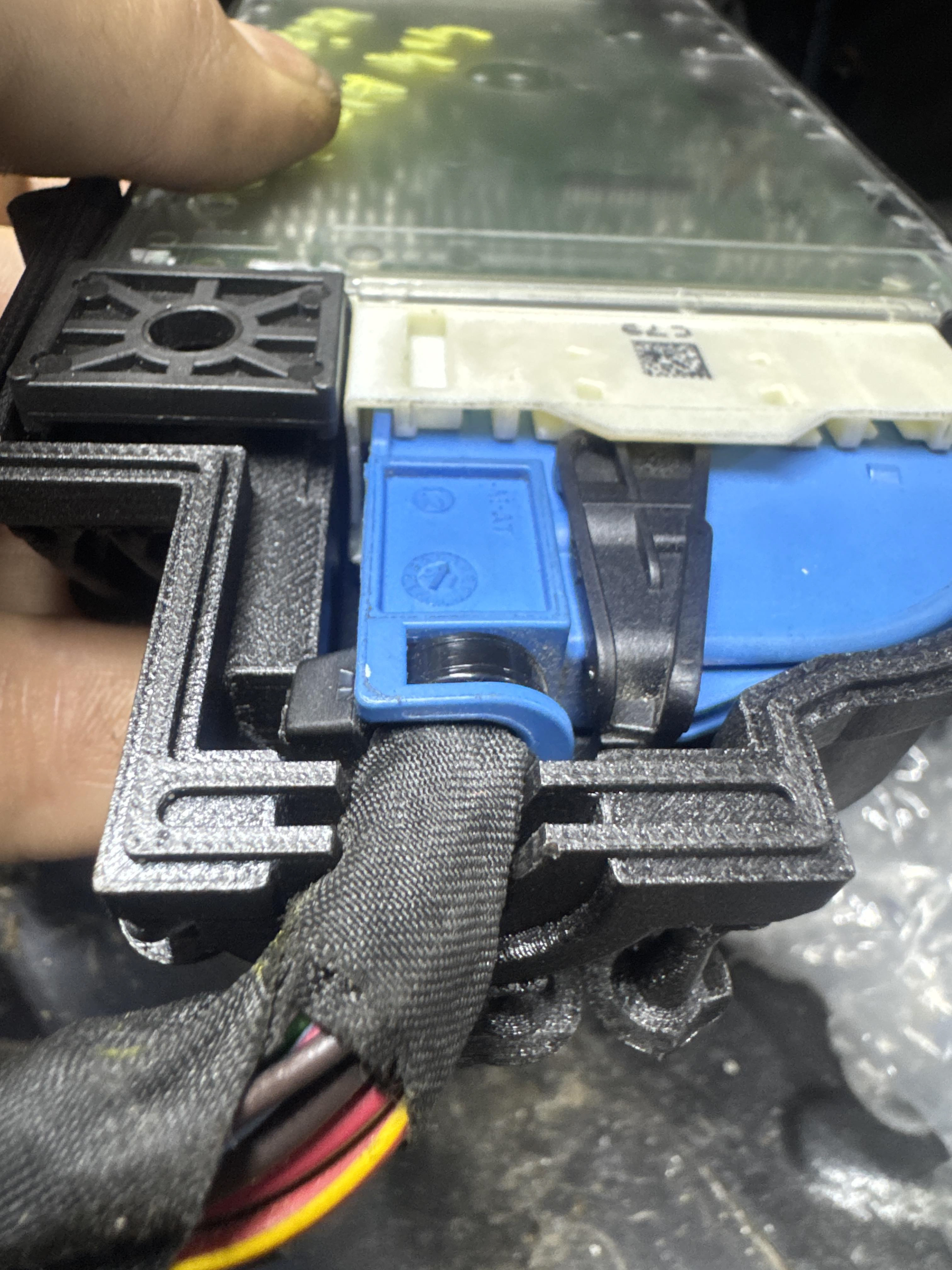

Exploded view of the enclosure

ROLE: Product/CAD Designer

Project description:

As the lead product designer, I was responsible for the full design process, from capturing accurate 3D models of the original keyless module to designing a robust sealing enclosure around it. The enclosure had to meet strict requirements for water resistance and durability while being fully producible via 3D printing. I recommended and integrated a combination of PETg for the rigid body and TPU for a print-in-place gasket, ensuring the final design provided a complete seal without the need for post-production assembly.

The project followed an iterative design approach, completing at least five design cycles to refine fit, functionality, and manufacturability. Autodesk Fusion was used to create a multi-material CAD model ready for 3D printing, optimized for both performance and production feasibility.

The final solution significantly improves the reliability of the keyless control module, protecting it from accidental failures caused by water or humidity. The combination of materials and print-in-place sealing design was both the main challenge and innovation, resulting in a practical, durable, and fully functional enclosure suitable for workshop-scale production.

This project demonstrates my ability to blend mechanical design, material expertise, and additive manufacturing techniques to deliver solutions that solve real-world technical problems with precision and reliability.