ROLES: Senior CAD Designer, Product Designer, R&D

Project description:

The market itself presented the design as a proposal, based on feedback from one of my customers who expressed potential demand for such hardware. I conducted rapid tests across various marketplace categories to identify initial customers and began promoting and selling the pieces.

Although the niche was extremely narrow and highly specific, it did not significantly impact the potential market size. Within just six months, I navigated through all stages of market growth. However, I encountered two main challenges towards the end:

Limited Traffic: The main marketplace traffic remained stagnant, with no noticeable increase on a monthly basis. The numbers that seemed reasonable at the beginning barely covered my operational costs. To address this, I needed to find ways to attract more traffic to our marketplace.

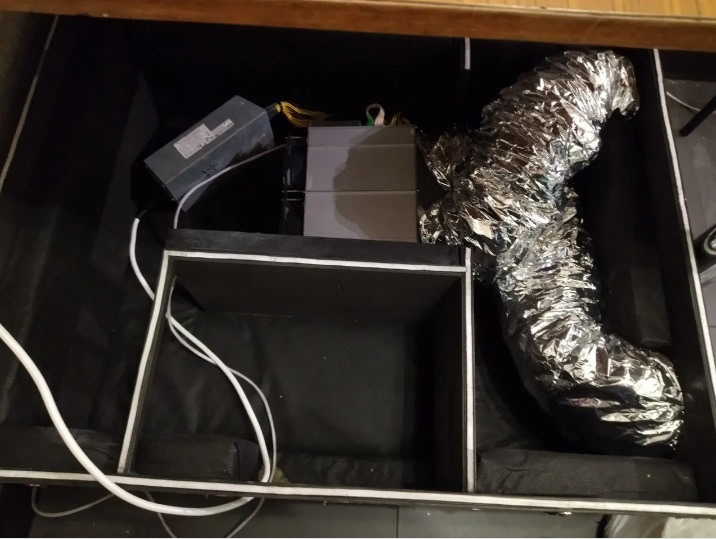

Market Expansion and Stock Issues: As the market grew, I faced challenges with maintaining stock availability and reducing shipping times. This prompted me to explore alternative production methods, specifically focusing on research and development for cardboard and vacuum forming sheet materials. By diversifying production methods, I aimed to address the stock shortages and streamline shipping times, ensuring a more efficient and timely delivery process for customers. In summary, while the niche market I entered was initially narrow and specific, it did not hinder potential for growth. Despite facing challenges with limited marketplace traffic and stock management, I remained proactive in finding solutions to improve operations and meet the increasing demands of customers.

Conducted roles:

ROLE: Research & Development Lead

Collected customer feedback for initial development and testing.

Gathered customer feedback for further functionality and feature development.

Conducted initial market research.

Explored and developed sales funnels.

Researched and developed the product range.

ROLE: Senior CAD-Designer

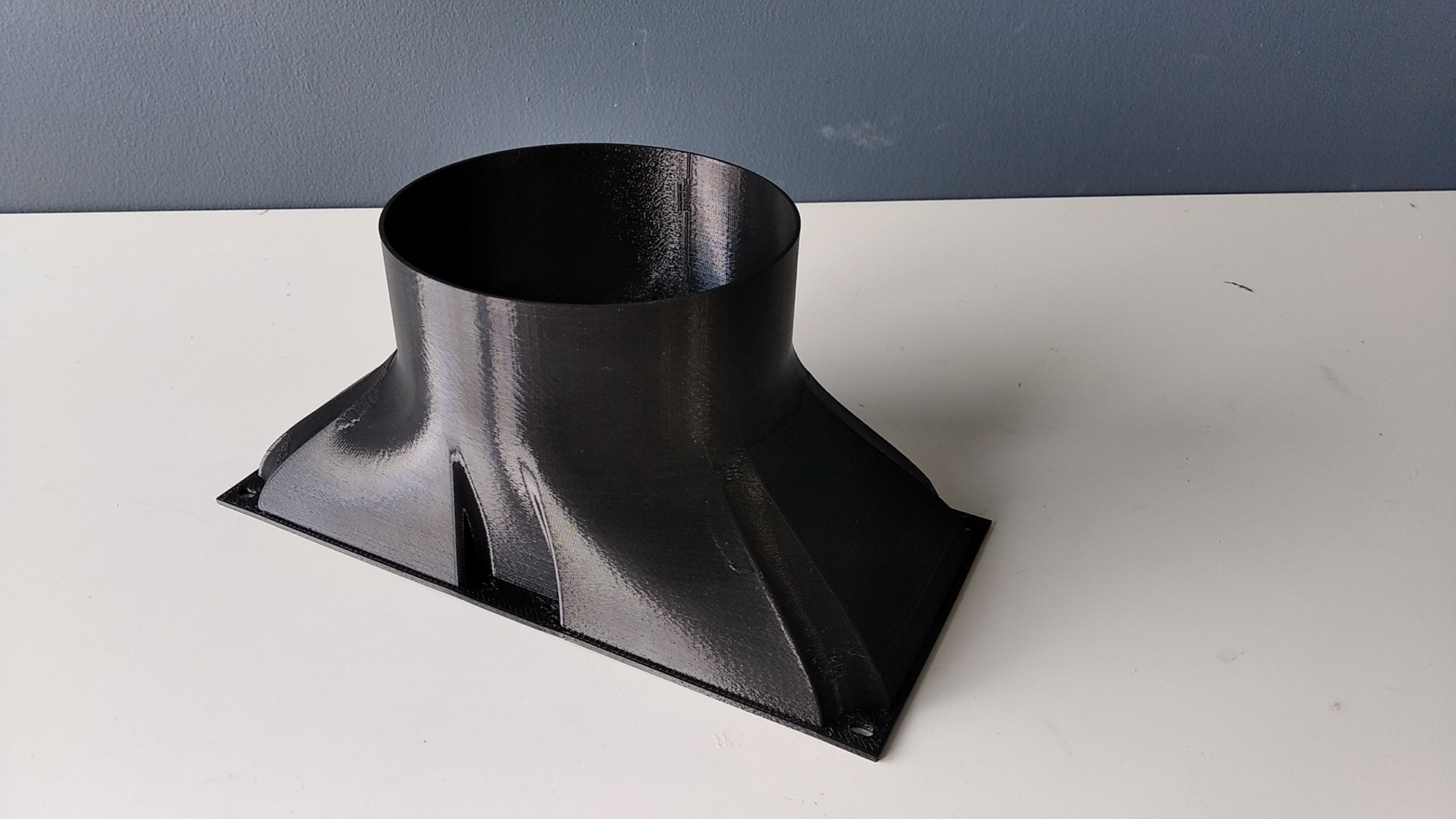

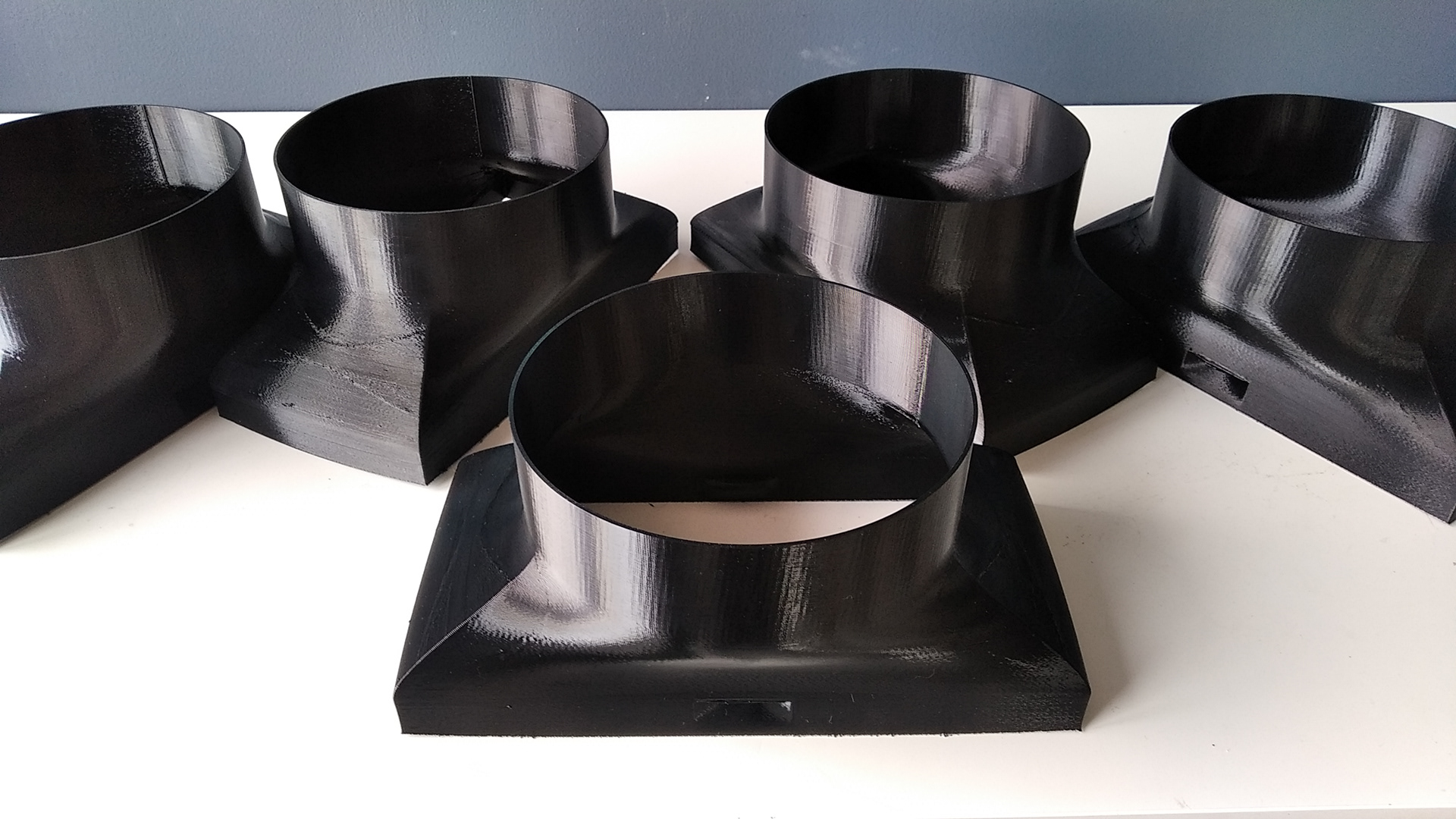

Full CAD and customer service for a niche hardware product aimed at crypto-miners.

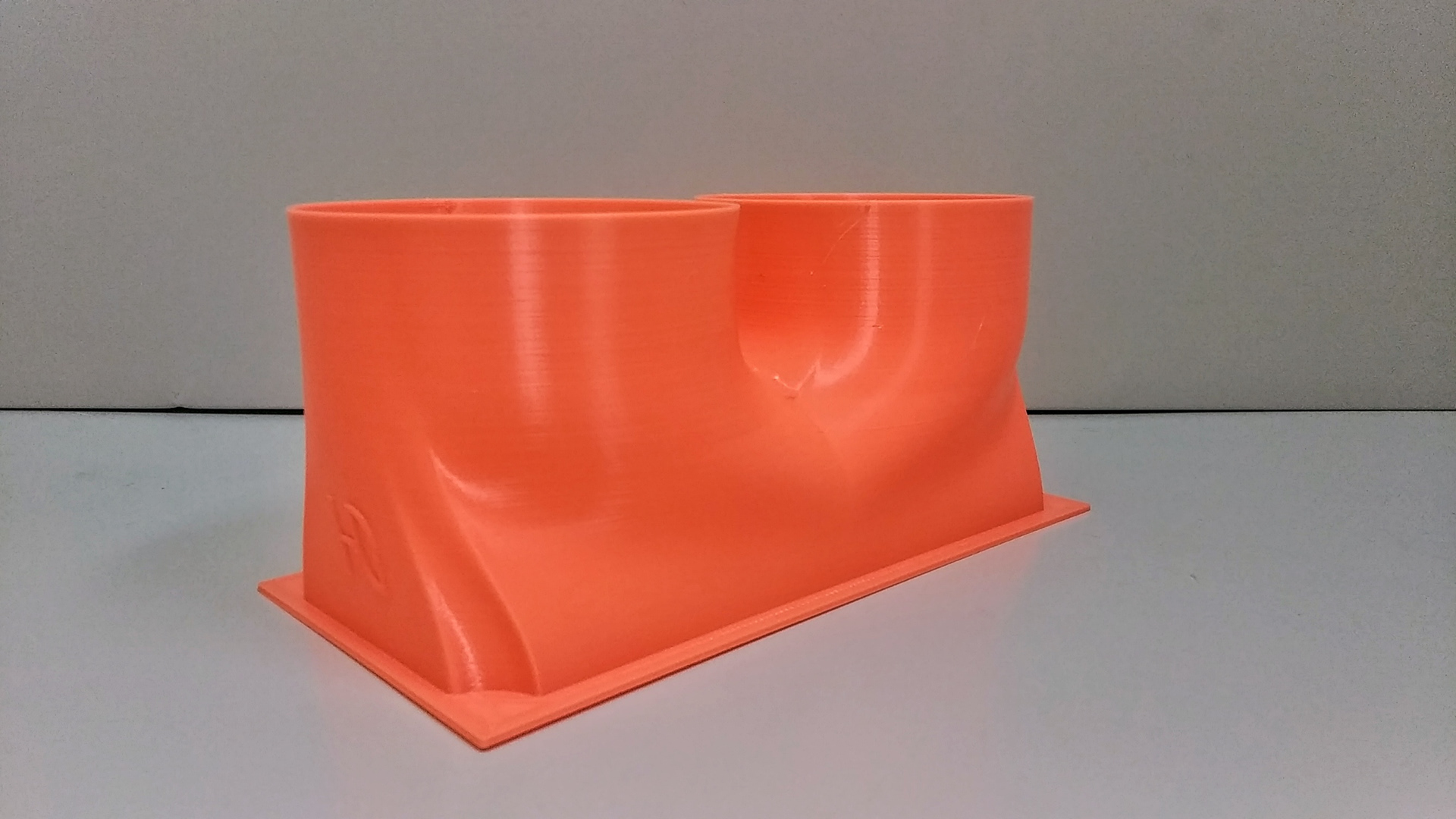

Designed around 20 unique 3D models for different miner modifications.

Created and implemented a unique functional feature, enhancing user experience and providing a competitive advantage.

Collected and managed technical requirements, dimensions, and tolerances for successful customer delivery.

Continuously improved production methods based on market changes and demand growth.

Adapted products for two different production pipeline designs: vacuum forming and cardboard punch cutting.

ROLE: 3D Printer Operator/Technician

Small scale 3D printing farm operation and maintenance

Technical maintenance of the FDM 3D printers: parts and accessories replacement and repair

Mechanical and Geometry repair of the 3D printers

Different nozzle size operation and maintenance

Video Surveillance system setup and maintenance

3D printers load schedule planning and maintenance