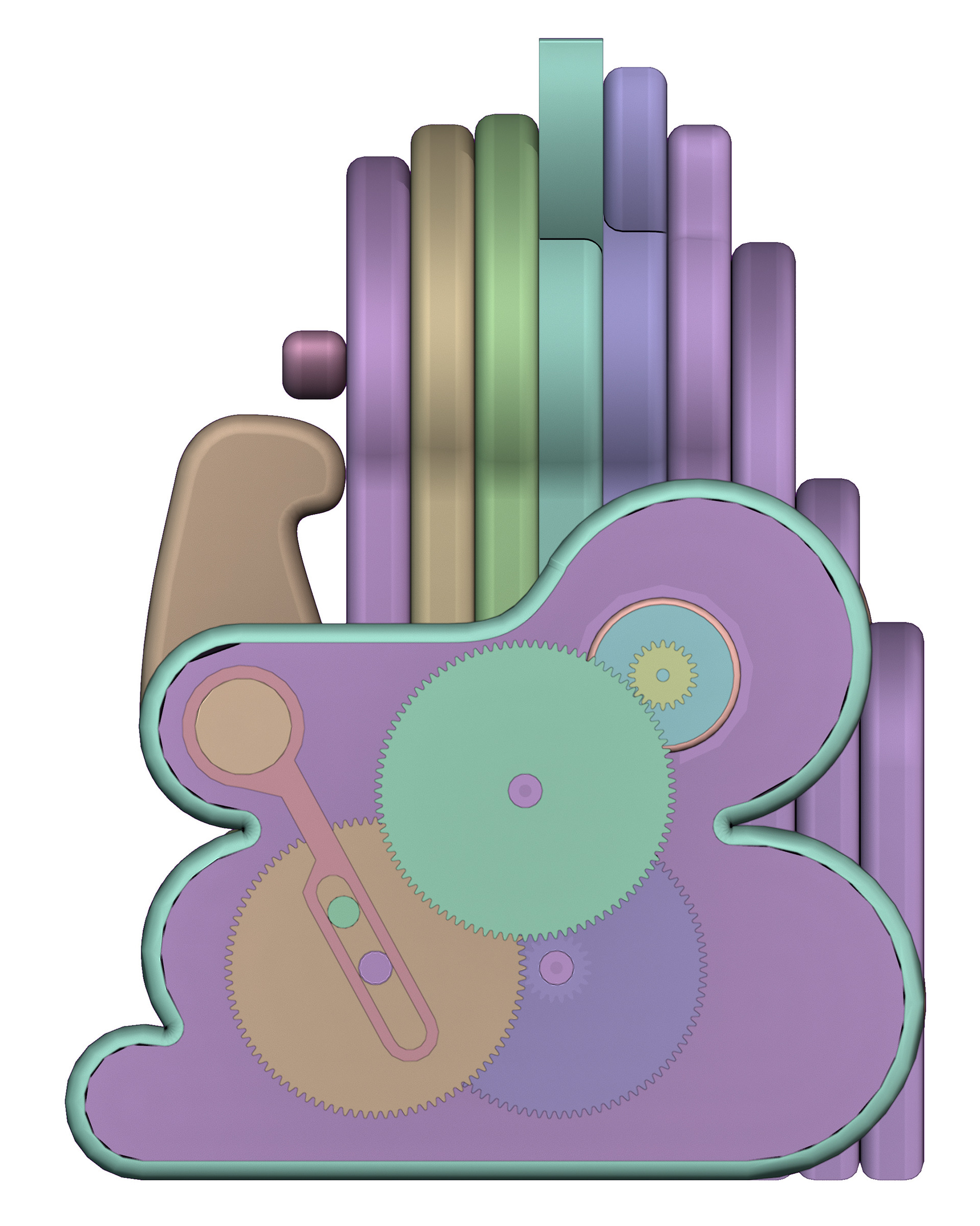

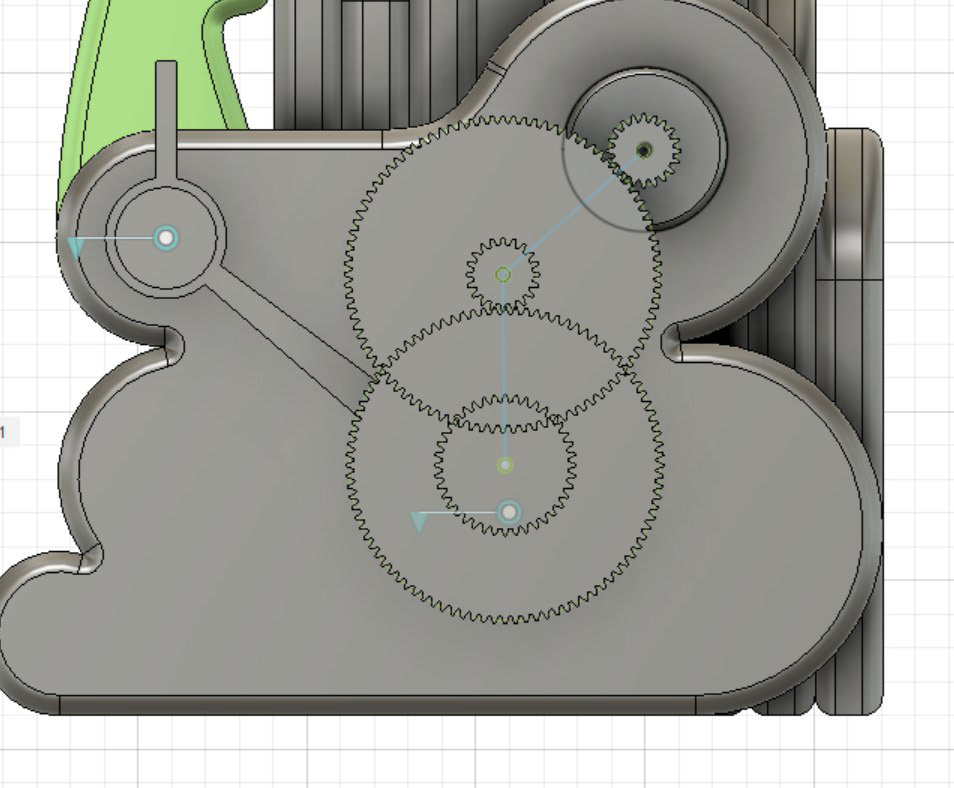

Production version of the layout

Production version of the layout

Poka Akop ArtWork for Alexey Rumin

Scope of work:

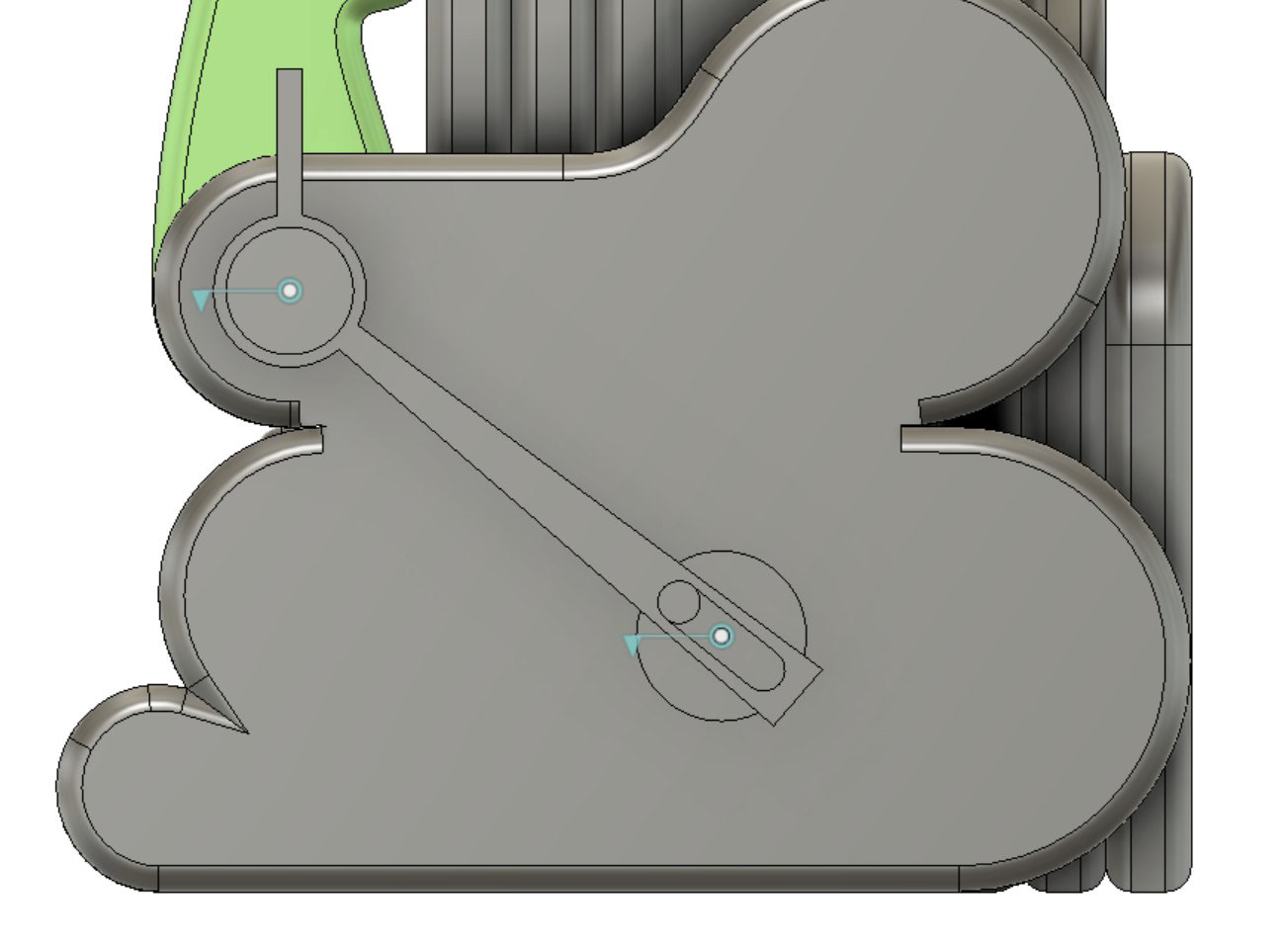

The main objective was to design and fabricate a mechanical solution for the paw, enabling it to move 'in' and 'out' of the body.

The constraint was an extremely tight space to accommodate all components, with the total height limited to 18mm (less than 3/4 inch).

The selection of the electric motor was based on this constraint, leading to the discovery that the best fit was salvaged from an old CD-drive motor.

Based on the motor's characteristics, I calculated the required gear ratio and determined the number of gears needed.

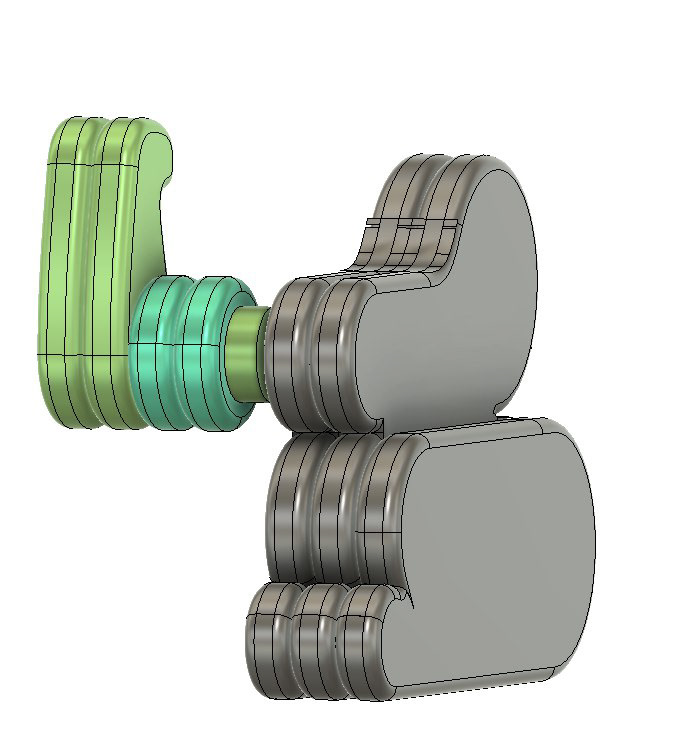

Subsequently, I designed a complete gear reducer system, including all necessary gears and a slider crank linkage.

The fabrication method primarily involved 3D printing, which also influenced the design due to the resolution limitations of the 3D printer.

Extremely fine gears were not feasible to print, necessitating at least one additional gear to achieve the required gear ratio.

Software: Autodesk Fusion 360

3D printer: Prusa I3mk3

Number of total gears: 4

Material: PET-g

Time spent: ~7 hours

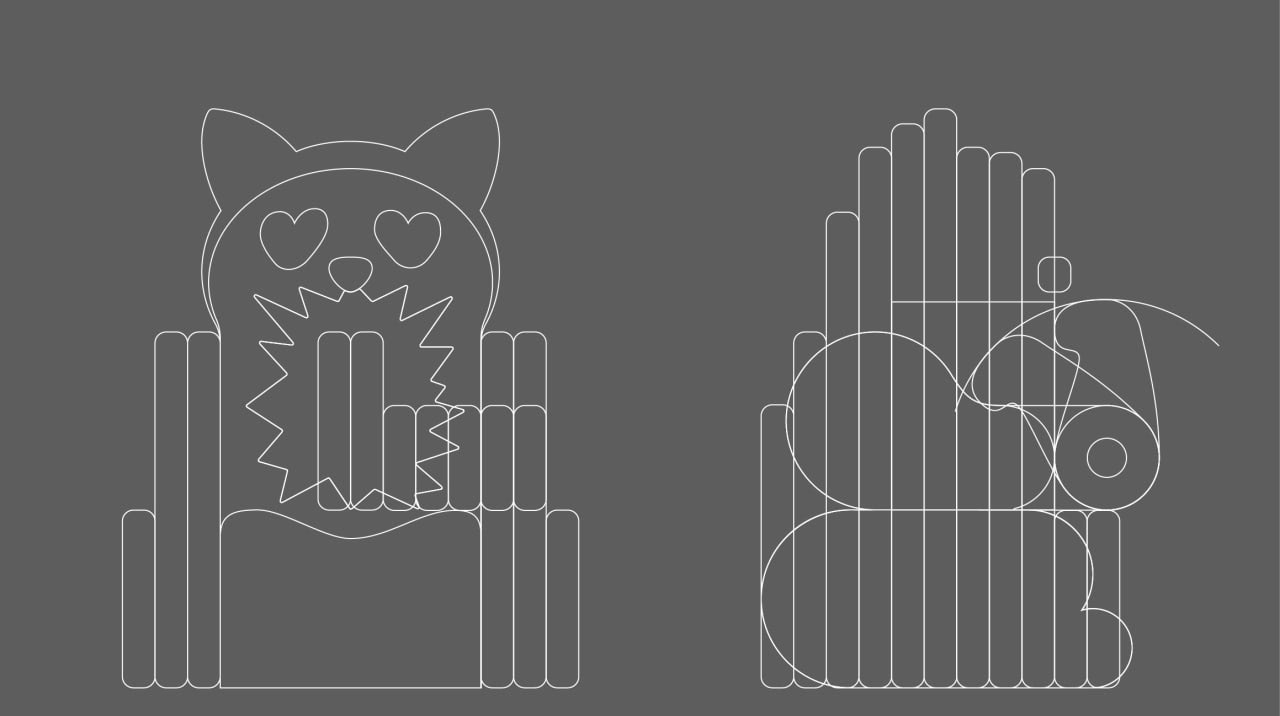

Initial specification of required movement

Initial mechanical concept

First version of the layout

Second version of layout

Selected drive

Gears